Vans 2025

A short film documenting a studio challenge to imagine design in the 2025 product year for lifestyle brand Vans.

Fall 2014

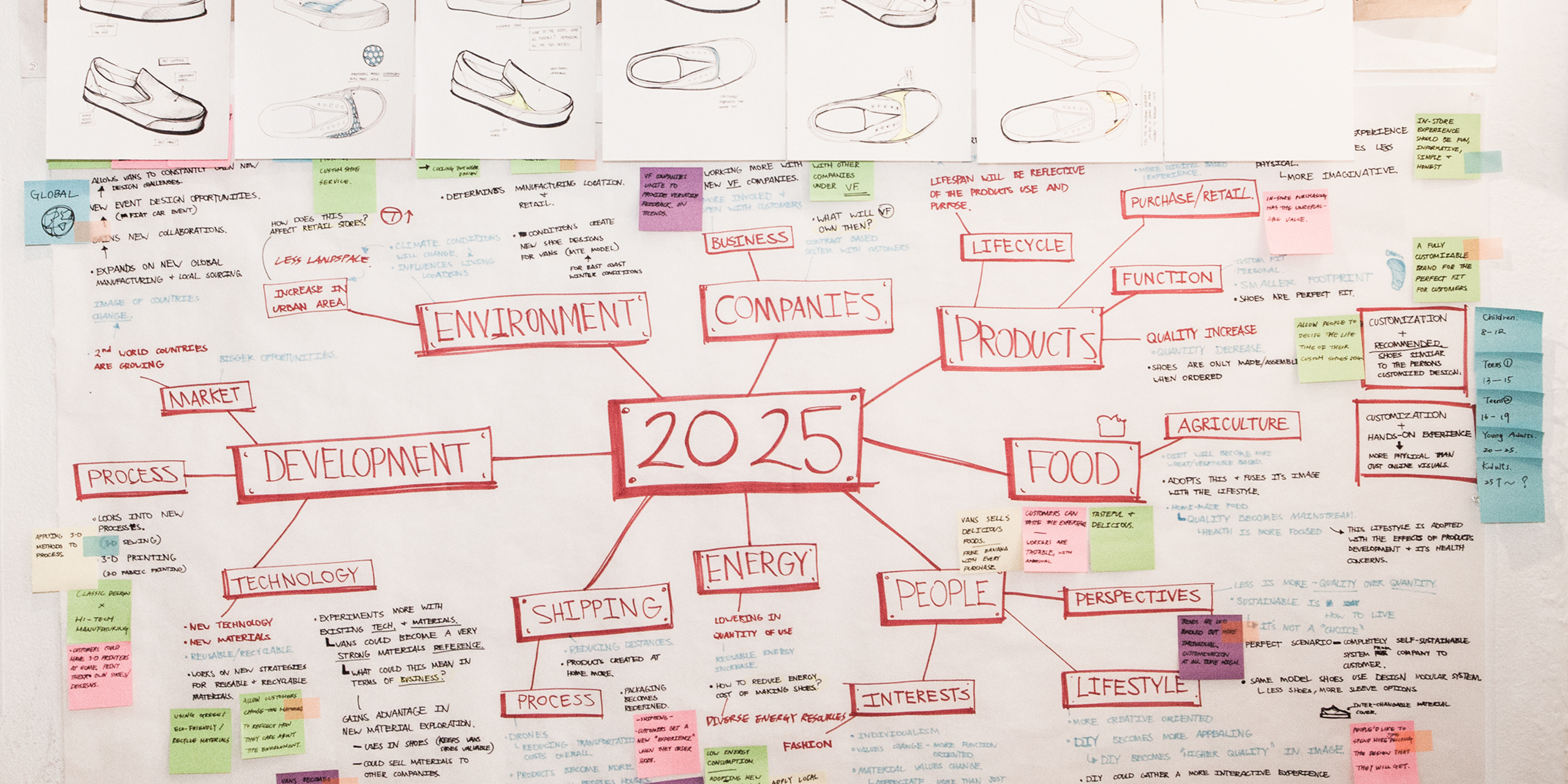

Southern California-based Vans sponsored a trans-disciplinary studio for students to consider the world of 2025, and how the iconic shoe/apparel/lifestyle company could engage future customers in a broader world market, while offering sustainable designs, transportation and manufacturing practices along with consumer-driven customizations.

A local maker of sticky sole skateboard shoes, Vans has become a multi-generational lifestyle brand celebrating Southern California culture.

Vans was founded in 1966 by Paul Van Doren and three partners who established the Van Doren Rubber Company in Anaheim which manufactured and sold skateboard shoes directly to the public. On opening day, 12 customers purchased shoes which were created in the morning and ready for pick up that afternoon.

In the early 1970s, Vans shoes became a cultural phenomenon. Designers added new offerings, collaborating with skateboarders and BMX riders for styles, and created shoes for other sports including baseball, basketball, wrestling and even skydiving.

Positioning itself on the forefront of SoCal youth culture, Vans sponsored Vans Triple Crown sport competitions, opened up skate parks, kicked off the Vans Warped Tour, and even financed the production of Dogtown and Z-Boys, a critically acclaimed documentary on skateboarding.

A touchback to its heritage, Vans launched Vans Customs in 2004 for customers to create their own shoes online using hundreds of color and pattern combinations. In-store kiosks, however, failed to engage consumers in creating customized shoes and many were discontinued.

Vans sponsored this Designmatters project, bringing together for the first time two upper-term courses, Design for Sustainability and Product Design 6: Innovation Studio. Students enrolled in both courses and worked on different aspects of the Vans challenge in each studio. This unique blending of sustainable and product design offered students a deeper design thinking experience that paired product/system ideation with business/financial considerations.

The studios challenged students to envision the world of 2025 and how design can set the stage for a revolution-in-making; one that concurrently responds to the needs of multiple stakeholders while also considering the natural environment.

Student teams investigated how Vans, a company synonymous with Southern California attitude, could evolve its existing product model into a successful product service system model.

All design concepts/responses needed to grow organically from the heritage of Vans as an internationally-known brand. Vans consumers are passionately loyal to the company, which needed to be honored and leveraged when developing new products, services and experiences.

Sustainability also informed the design process at every step. Product life cycles were instrumental in determining the project concept parameters at all levels from initial design to manufacturing to end-of-life. Social and cultural sustainability needs were also addressed along with ethical considerations (keeping jobs local, labor needs, agricultural practices, etc.).

In addition to creating a sustainable item/service/experience, teams were instructed to capitalize on the burgeoning customization trend to make individual consumer-driven products economically feasible and procedurally attainable—reminiscent of the original Vans experience where consumers played an influential role in designing and creating their own pair of shoes.

Currently, Vans creates and sells 60 million pairs of shoes annually, with only 40,000 pairs customized. That number is expected to grow dramatically in the coming years. More than 100 hands, however, currently touch a shoe from beginning to end during the manufacturing process, which would be overwhelming for any customization addition.

To help Vans achieve customizations on a global scale, design teams would need to streamline current manufacturing strategies to be cost effective and less labor intensive while simultaneously fulfilling sustainability requirements.

Additionally, students were encouraged to incorporate future technology (digital interfaces, 3-D printing, etc.) into their design concepts.

What impressed me the most was the ability of the students to stay connected to who we are as a brand without working within our walls. They showed a clear understanding of the culture and expectations of not only customers but also the people who make the company what it is.

– Safir Bellali, Director of Design Innovation, Vans

This design and sustainability challenge directed students to create a Vans product, service or system, and chart out the timeframe for its rollout in the community and for consumers.

Working in teams, students focused on the environmental and social/cultural consequences of their product/service life cycle. They delved into the footwear arena, analyzing products and processes, creating customer/user profiles and presented best practices and product designs that focused on customer interaction that could evolve as a viable business model and successful sustainable brand strategy in the decades to come.

At the beginning of the term, presentations by the Vans leadership team provided initial organizational background and deliverables that Vans deemed beneficial for their long-term planning and strategies.

Vans provided students an “Open Door” policy to Vans representatives. Students were also given opportunities to examine shoe material samples, and were encouraged to visit and tour Vans Southland-based retail stores.

These early Vans contacts often ricocheted student thinking and propelled further investigations into information and resources outside of Vans as students connected to professional leaders in new technology, ecofriendly materials and sustainable practices.

To immerse themselves into the world and workings of Vans, students were assigned to present a case study on specific Vans products, revealing the analytical process behind every detailed step of the product life cycle. Profiles of typical Vans multigenerational consumers of today (and potentially tomorrow) were also part of researching the current dynamic Vans landscape.

Designing for consumer-driven customizations was an important theme throughout the studio. Like the original Vans customer experience in the 1960s, this studio asked how consumers of the near future could be “co-creators” for specific products and experiences, requiring students to come up with inventive concepts to answer those questions.

The Life Cycle to Design (L2D) methodology directed all steps of the design process, guiding students to analyze their entire life cycle process from raw materials, extraction, manufacturing, packaging, transportation, retail, use and end-of-life. This rigorous and complicated template, depicting the environmental and social/cultural consequences, was vital in creating and refining their projects, especially in light of new customizations, sustainability and financial business models.

Teams constantly referred back to their original life cycle study to gauge specific chart improvements on their overall design; this sharpened students’ claims from merely stating that a certain element made the product/system “environmentally friendly” to producing factual data on how individual life cycle improvements were really a sustainable choice.

To accommodate the proposed mass customizations integral to their life cycle, student teams designed tangible strategies (often incorporating new technologies) to update and restructure current manufacturing systems to reduce labor costs, increase product value and satisfy sustainability goals.

Students’ passion for the Vans brand and excitement to build on its success was evident in the wide variety of directions that teams explored, investigated and ultimately presented at the studio final held at the Vans California headquarters in Cypress. Along with fellow students and faculty, Vans employees from all levels were welcomed in the audience and provided feedback, asked questions and commented on the student’s final presentations.

We teach students that they have to be able to back up their design decisions by giving them the tools that can help them determine true sustainability. A lot of designers working today will call something ‘eco-friendly,’ ‘environmentally friendly’ or sustainable, but they haven’t done the life cycle. They will call something sustainable just because it’s made out of bamboo, but in some cases that bamboo fiber may not be the most sustainable choice. Our students know the process of research to back up any claim they make about sustainability.

– Heidrun Mumper-Drumm, Director of Sustainability Initiatives, Art Center

Renee Mascarinas and Maryann Mochi Chi

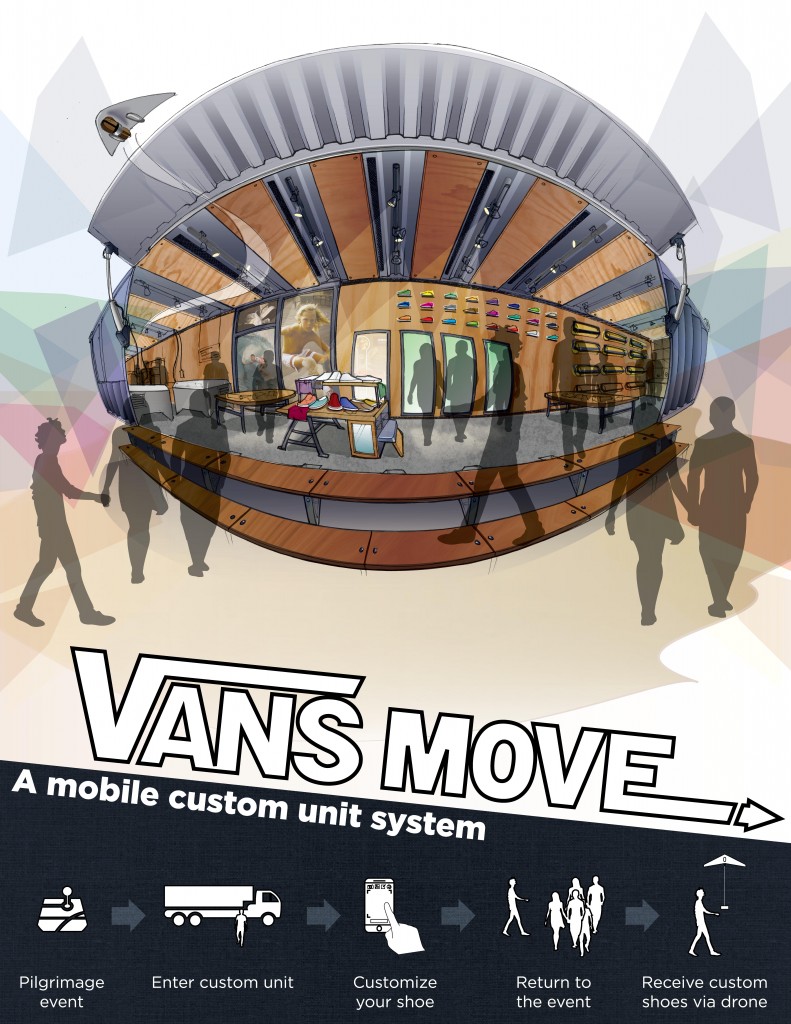

Vans on the Move uses burgeoning technology to bring the Vans brand directly to the people through mobile custom units, shoe customizations and an annual pilgrimage event.

Vans on the Move uses burgeoning technology to bring the Vans brand directly to the people through mobile custom units, shoe customizations and an annual pilgrimage event.

Six green-powered mobile customization units tour the country allowing customers to create their own shoes, choosing either pre-sets or their own designs. Each mobile unit is dedicated to one aspect of shoe manufacturing and custom treatments. Customers are alerted via an App when the next unit is scheduled to arrive. Overhead, solar-powered blimp drones are inventory warehouses for the mobile units; small drones deliver materials to units as well as finished shoes to customers.

Debuting in 2025, the SoCal Vans pilgrimage event celebrates with food trucks, music, sports and access to all mobile custom units in one place so customers can create their pair of shoes in one day – just like the first Vans customers did.

Jeremey D’Ambrosio, Justin Deandrade and Ian Dowling

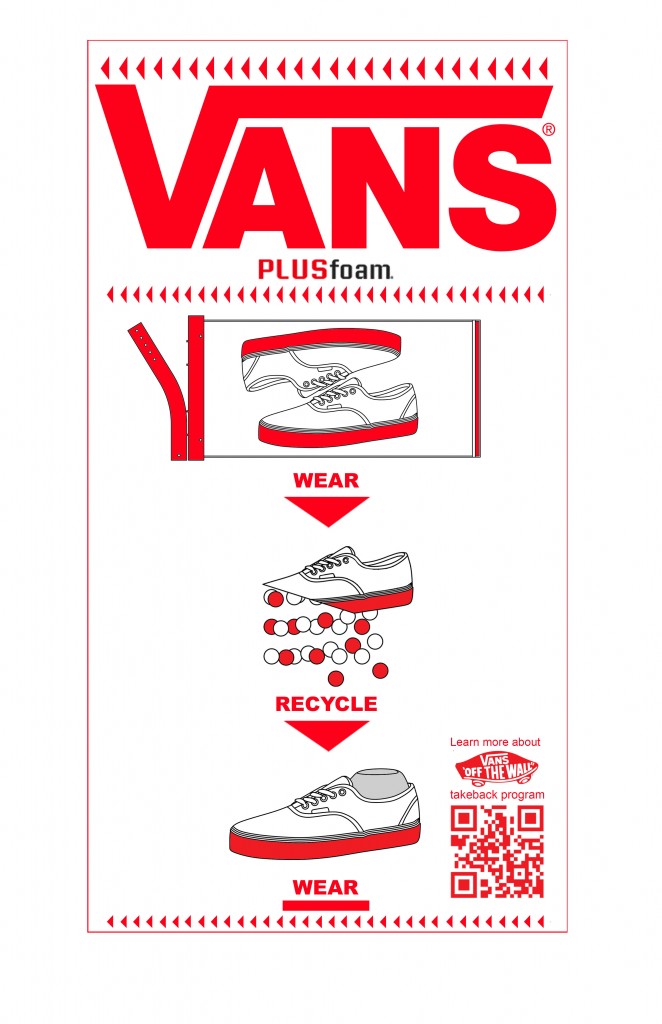

This proprietary manufacturing and customization system envisions a durable, recyclable shoe of the future, an innovative process for individual personalization, and a take back program that benefits Vans, the consumer and the environment.

This proprietary manufacturing and customization system envisions a durable, recyclable shoe of the future, an innovative process for individual personalization, and a take back program that benefits Vans, the consumer and the environment.

Pellet-sized biodegradable materials currently produced by Plus Foam, a Vans subcontractor for insoles, are leveraged for shoe construction. Through the Thermofoaming process, shoe components are joined together thermally, minimizing the manufacturing process to just a singular assembly, thus greatly eliminating petroleum-based materials and off-gassing glues.

Digital sampling via 3D imagery allows creative customizations for Supply on Demand “direct to material printing” that can be employed at all Vans international manufacturing locations.

Well-worn and damaged shoes are sent back to Vans in pre-paid envelopes for customer credit. Vans reprocesses old shoes in future manufacturing, thereby closing more of the supply loop.

Shane Li

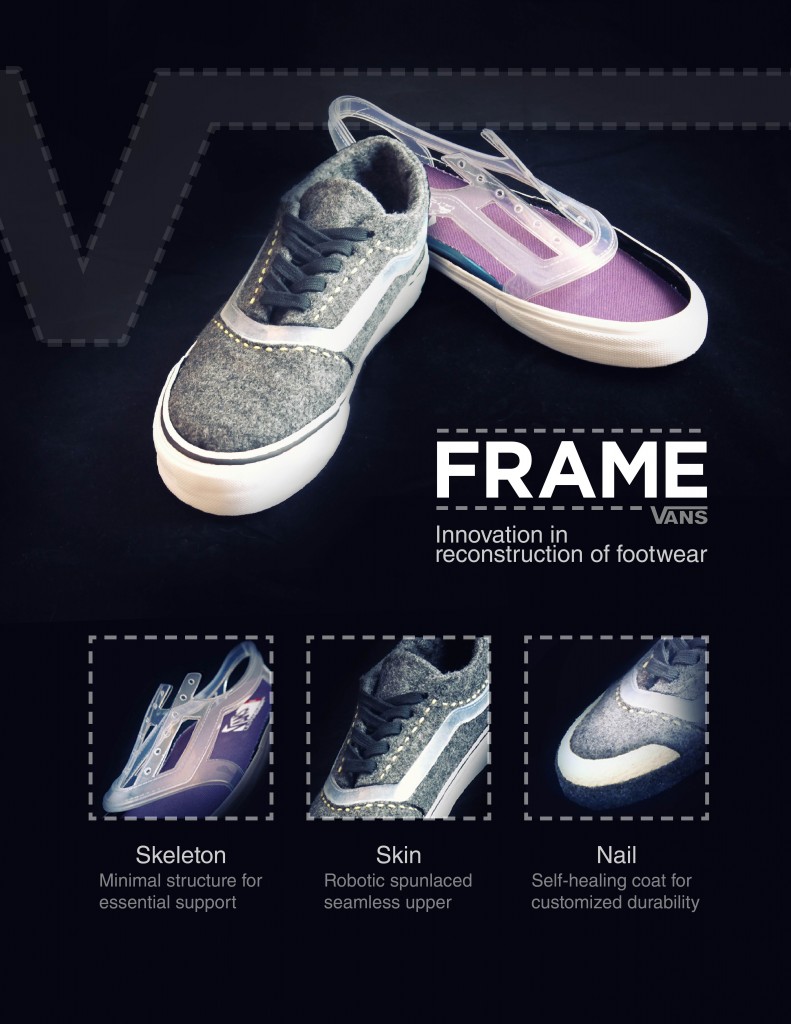

Reimagining the way footwear will be designed and constructed in 2025, Frame presents sustainable alternatives in materials and manufacturing methods that result in a product that utilizes less materials/energy overall but still delivers a solidly constructed, deeply personalized shoe.

Reimagining the way footwear will be designed and constructed in 2025, Frame presents sustainable alternatives in materials and manufacturing methods that result in a product that utilizes less materials/energy overall but still delivers a solidly constructed, deeply personalized shoe.

Frame involves an innovative robotic automation process that uses no glue, exchanges much of the petroleum based materials with recyclable components and expands the lifespan of the shoe with sustainable elements.

Frame’s redesign is threefold. The Skeleton is a streamlined support piece composed of strong recyclable thermoplastic rubber. The Skin employs a fully robotic hydroentanglement process that leverages water jet power to fuse the spunlaced seamless upper to the support structure. The Nail is a protocell coating that can be reapplied when damaged or worn; it’s also customizable for thickness, patterns, texture and color.

Yu-Ting Chen, Carolina Rodriguez, Susan Zhang

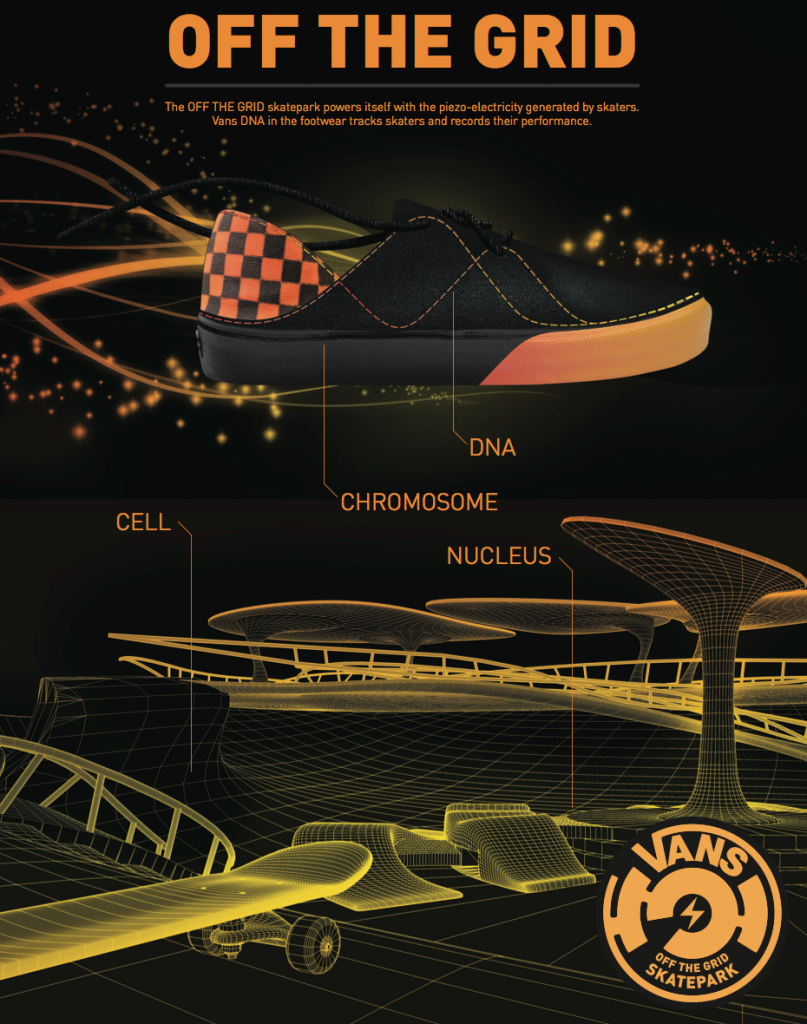

Off the Grid is an interactive customer-centric Vans skating park of the future that taps into power generated by Generation Z skaters.

Off the Grid is an interactive customer-centric Vans skating park of the future that taps into power generated by Generation Z skaters.

This retooled Van skate park takes advantage of the piezoelectric effect (kinetic energy from applied stress and collected vibrations into electric energy); skaters going over obstacles create renewable energy that will fuel the park’s power needs and reduce carbon emissions. Integral to the concept is a redesigned Vans shoe with built-in RFID tag, which records skate use, energy created and other stats.

Rolled-out first as a traveling skate park to generate customer excitement, Off the Grid will debut in 2025 with permanent parks where technology-driven youth use updated DNA shoes with embedded RFiD to earn energy credits, “turn” on lighted obstacles and share photos/info via social media platforms.

Daniel Bromberg and Erick Ikeda

Drawing on the growing global reach of Vans, which currently has manufacturing plants in seven countries, Hubba hyper-regionalization empowers world cultures to celebrate their heritage by engaging in the design, creation, transportation, distribution and sale of unique one-off products not originally intended for mass market production.

Keeping as much of the supply chain as local as possible reinforces a cultural respect dynamic, produces less carbon footprints and is reminiscent of Vans heritage as trend innovator.

Hubba will be piloted in Brasil where locality will be embraced: local artists for designs, local materials in manufacturing, existing transportation methods (bikes, mopeds, etc.) for distribution, and sales and merchandising opportunities/experiences where crowds typically gather.

Once many Hubbas have been established, Vans will curate a new line of global products that eventually would be desired by customers all over the world.

I did a lot of sewing and hand-making in this class to find an appreciation for what technology can do for manufacturing. Experiencing what would take so long to do with my two hands showed me the human limits and how technology moves us forward.

– Erick Ikeda, Student, Product Design

Devin Procter and Tina Tsung

Viewing climate adaption through the lens of local manufacturing, Explore considers footwear customizations as a solution to the practical challenge of producing a Southern California-styled shoe for diverse global markets.

The seven current Vans manufacturing plants around the world would produce shoes best suited for their specific climate conditions (dry/wet, hot/cold, humidity, etc.). Climate adaptions are “hidden” inside design: cold climates use thick materials to trap heat inside; monsoonal climates feature mesh insoles for water drainage, etc.

Each global manufacturing plant would tackle customized climate needs, thus shipping, distribution impacts would be minimized. Retail stores could buy old shoes, replacing and/or reselling pairs. Online customers around the world could purchase used shoes from an exotic location for added value.

Adding design concepts: aging shoes would contain a printed pattern that would slowly appear underneath the top material layer. Eyelets would employ sewed threaded patterns and colors instead of metal and glue materials.

The student projects hit all parts of the spectrum and were very forward-thinking, that’s exactly what we wanted. Some of what the students presented could very well happen in the next five and even ten years out. Some we are actually thinking about right now –and they didn’t even know that.

– Ryan Biggs, Innovation Design Engineer, Vans

A short film documenting a studio challenge to imagine design in the 2025 product year for lifestyle brand Vans.

A behind the scenes look into the design process of students in the Fall 2014, Vans sponsored trans-disciplinary studio.

A behind the scenes of the Fall 2014, Vans sponsored trans-disciplinary studio and the design challenge of consumer-driven customizations.