The following blog post was written by Graduate Industrial Design Student, Margaret Frye about her recent trip to Ahmedabad, India as part of a collaborative studio class with CalTech, taught by professor Ken Pickar.

In December 2013, graduate Industrial Design students Margaret Frye, Anastasia Hanan and Product Design student Shirley Rodriguez traveled to Ahmedabad, India with CalTech professor Ken Pickar’s Product Design for the Developing World class.

Day 1

At 4am on a Sunday in mid-December a group of 15 students touched down in Ahmedabad, India.

With disciplines ranging from mechanical and biomedical engineering to computer science to product and industrial design, we had come together for Caltech’s Product Design for the Developing World course not knowing exactly where our fieldwork would take us, but with the shared intent of doing work with impact, and the confidence that our respective skills would create the momentum necessary to bring powerful solutions to fruition.

Our Indian hosts were an equally diverse group hailing from across the country and studying in various fields at IIT Gandhinagar, one of India’s premiere technical institutes.

Our Indian hosts were an equally diverse group hailing from across the country and studying in various fields at IIT Gandhinagar, one of India’s premiere technical institutes.

We wasted no time in our initiation; by the end of the day we had sampled paneer, roti, and mango juice (a popular favorite) and been briefed on local industries, challenges, and a range of previous design solutions both successful. We then boarded the “Ambica” – our bus and trusty conveyor for the week – to visit the Sabarmati ashram, Gandhi’s home base for 12 years and the place from which the Salt March commenced.

Day 2

Our first site visit took us to The Polio Foundation, an NGO medical center that now serves over 100 communities across India and provides surgery, prostheses, and treatment for cerebral palsy, amputees, club foot, and countless other handicaps and maladies. The team visited the Ahmedabad hospital and toured facilities for patient recovery, occupation therapy, and prosthetic fabrication and also spoke with directors about the foundations needs and future plans.

Day 3

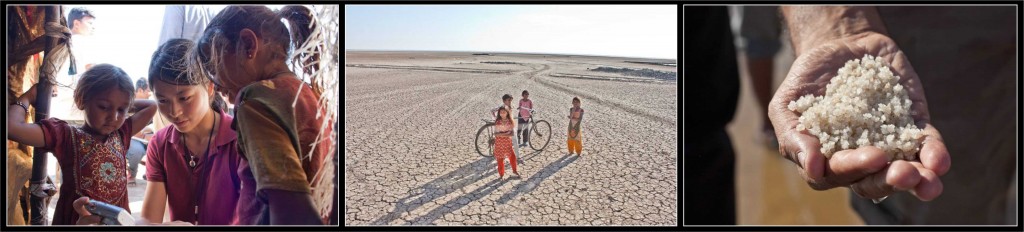

A 3-hour drive from Ahmedabad, Little Ran of Kutch has been a site for salt harvesting for over 600 years. A remote community in coastal Gujarat, it is home over 50,000 migrant workers and their families who spend 8 months out of the year preparing work sites and performing the occupational hazard-ridden job of maintaining salt pans with limited human contact, very few basic resources, and no government recognition.

We spent a day in the field interviewing salt-workers and trying the work ourselves, investigating labor practices, community dynamics, and methods and techniques employed in their work.

We spent a day in the field interviewing salt-workers and trying the work ourselves, investigating labor practices, community dynamics, and methods and techniques employed in their work.

Day 4

For our third trip, we visited the massive medical campus that is home to the Spine Institute, a government-run school and hospital providing low-cost care and occupational training to patients undergoing treatment for spinal conditions.

We were able to sit in on a group therapy session for wheelchair-bound patients, visit the prosthetic fabrication shop, and tour the facilities used for various therapy regimens, minor procedures, and tests.

We were able to sit in on a group therapy session for wheelchair-bound patients, visit the prosthetic fabrication shop, and tour the facilities used for various therapy regimens, minor procedures, and tests.

Day 5

SEWA, the Self Employed Women’s Association, hosted the final two days of site visits for our group. A trade union for the informal workforce, their primary goals are to educate and prevent occupational hazards at the primary level, and connect women with resources like insurance and childcare.

We visited three work sites of self-employed women laborers; a construction lead and her crew adding a second floor to a home, a group of teenage girls employed after school to roll incense, and a neighborhood production line – each home with its own operation – making kites.

We visited three work sites of self-employed women laborers; a construction lead and her crew adding a second floor to a home, a group of teenage girls employed after school to roll incense, and a neighborhood production line – each home with its own operation – making kites.

Day 6

Our second day with SEWA took us outside Ahmedabad again, this time to Naroda, a small agricultural area.

There we went to several farms to meet the farmers and the laborers involved in various facets of the process: pesticide spraying, seed sowing, irrigation, cotton picking, crop harvesting, and fertilizing.

There we went to several farms to meet the farmers and the laborers involved in various facets of the process: pesticide spraying, seed sowing, irrigation, cotton picking, crop harvesting, and fertilizing.

Day 7

After a week of thorough immersion, Saturday was a day of listening and learning, with multiple lectures from doctors, designers, and entrepreneurs, including our host Professor Bhaskar Bhatt, a mechanical engineering instructor and alumnus of India’s National Institute of Design. Several students were also given the opportunity to travel to the nearby campus and get a taste for design education in India. The school was founded with support from Charles and Ray Eames, and we were fortunate enough to visit right in the middle of their grad show.

Day 8

We had spent a rich week in the field, which naturally generated a torrent of ideas for products, systems, and solutions. After intense deliberation, project proposals were narrowed down and before our reluctant goodbyes, the Indian students attempted to teach us a few things about kite-flying on the roof.

Next Steps

Over the next several months, interdisciplinary teams of students will be continuing research and development of product designs that originated from our visit to Gujarat. Please stay posted for details of our progress and our developing partnership with IIT.